TRANSVAC

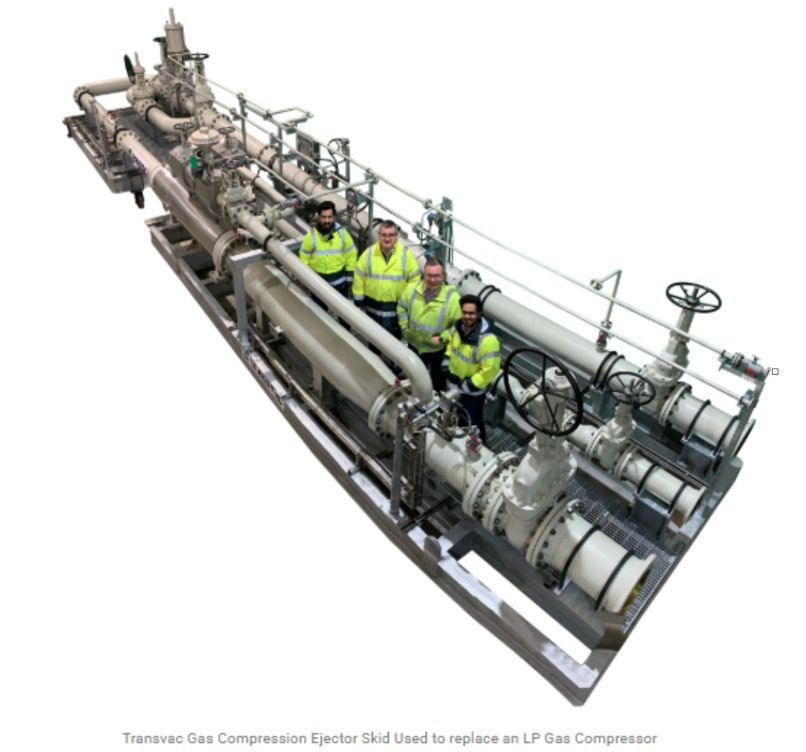

Ejectors are static, pipework-based compressors. As such, they are ideally suited to Gas Compression as they have no moving parts, require zero maintenance and can be installed in the same way as regular pipework. This simple design makes Ejectors very cost effective when compared to traditional compressors and well suited to ‘regions of conflict’ where equipment maintenance often requires expensive security considerations.

Ejectors use a high pressure ‘motive’ stream to drive their operation. In many cases, they can utilise existing or ‘waste’ gas or liquid streams to allow them to operate. For projects where existing high-pressure gas or liquids are readily available, the use of Ejector technology becomes a ‘no-brainer’ when compared with mechanical gas compression technologies. This opportunity to use waste energy is unique to Ejectors and makes a compelling business case with respect to OPEX and CAPEX, as no ‘new energy’ is required to run the Ejector.

Ejectors are commonly used to replace, or as an alternative to;

- Liquid Ring Compressors

- Oil Flooded Screw Compressors

- Dry Screw Compressors

- Sliding Vane Compressors

- Centrifugal Compressors

- Reciprocating Compressor

Transvac Steam Ejectors; also known as Steam Jet Ejectors or Steam Eductors are used for creating vacuum across many industries. Applications range from coarse vacuum single stage Steam Ejectors; such as rapid evacuation Ejectors (also known as ‘Hoggers’) up to 5 stage Steam Jet Ejector Systems fully packaged to produce vacuum levels of up to 25 microns Hg abs.

Modern, energy efficient Steam Jet Ejector Systems offer many advantages when compared with other vacuum producing systems, such as mechanical Liquid Ring Vacuum Pumps, Rotary Vane or Screw type Vacuum Pump. Steam Jet Ejectors can often utilise surplus motive steam sources on site and need no additional energy.

The most reliable of all high-vacuum systems

Ideal for handling large and contaminated suction loads

No moving parts

Low noise levels

Minimal and non-specialist maintenance

Can be made from corrosion resistant materials

Easy to retrofit or uprate should the process change

Custom-designed to each application

No ATEX considerations

100% efficient (if using available waste steam energy)

Low cost solution

Proven Technology